Plastic 2 Build

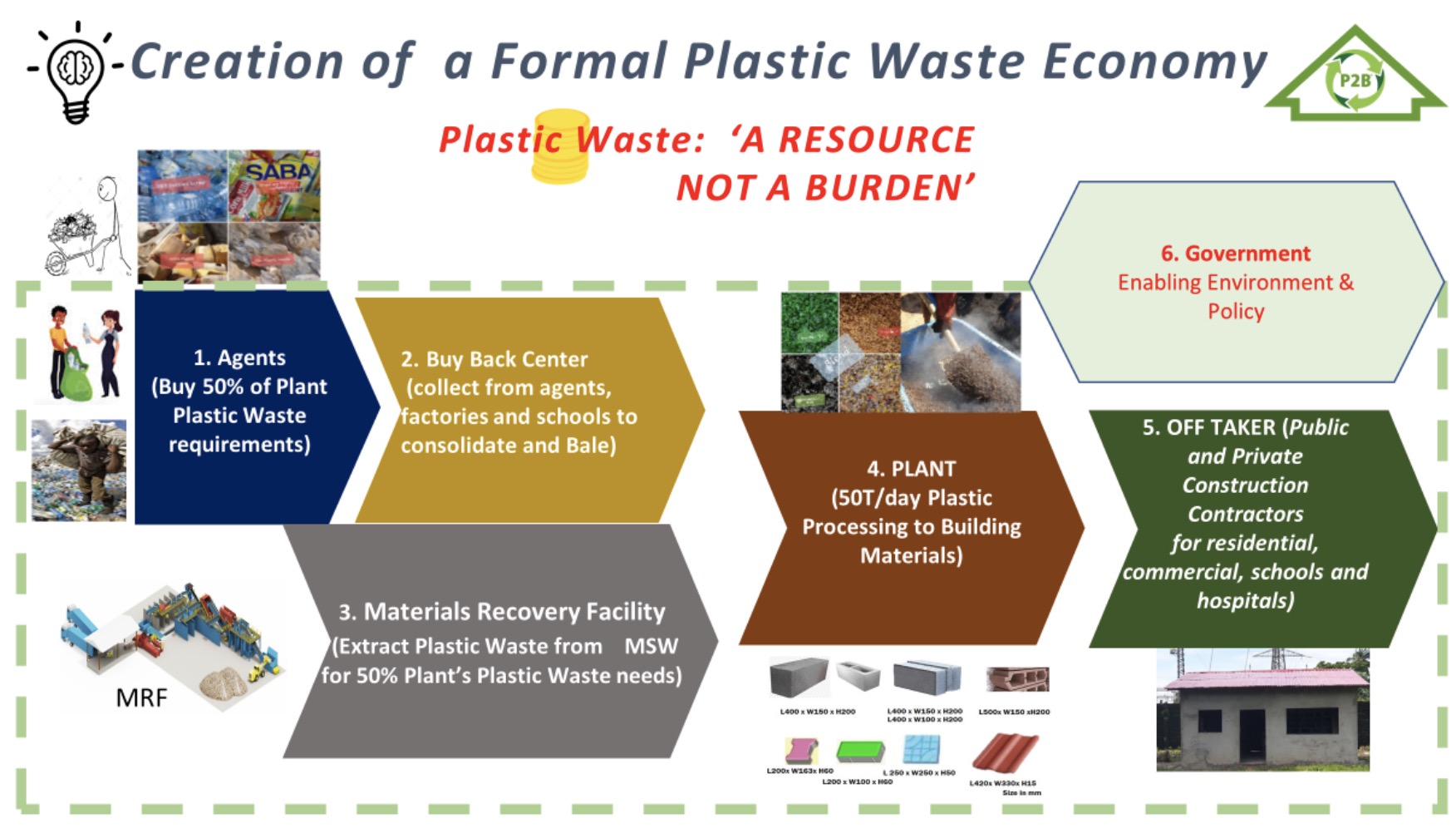

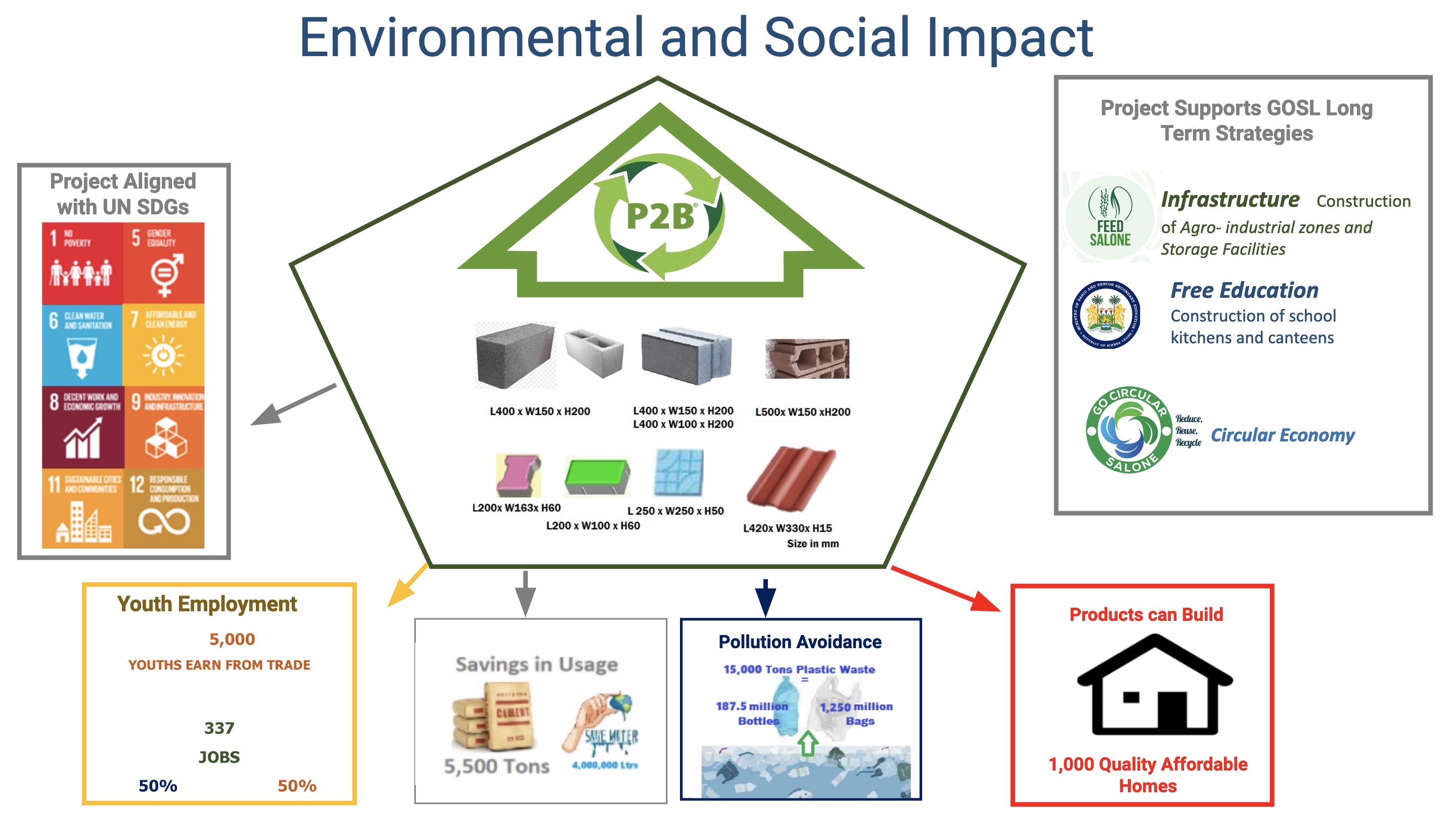

Plastic 2 Build (P2B) is the flagship project formalizing the plastic recycling sector, focusing on the procurement and extraction of plastic waste from the environment (reducing plastic pollution) through lower income persons and communities (creating wealth and jobs), repurposing them to affordable building materials for low-cost housing while aligning with 8 SDGs and adhering to circular economy principles and gender empowerment.

The Problem

The following issues have been in the limelight in recent times due to urbanization and population growth affecting the lives of citizens of the world:

- Plastic Pollution: Plastic is part of our daily lives, we have to face reality, Plastic is here to stay. It is predicted that by 2050, there will be more plastic in weight than fish in the oceans. Freetown is contributing 27,000 tons to annual plastic pollution figures.

- Slum Dwelling: 1 billion people on earth live in Slums and Freetown is no exception with a quarter of its population living in unhealthy and undignified conditions.

- Youth Unemployment: 90% of youths live in the global south. 70,000 in Freetown are unemployed.

Leaders have attempted to solve these problems with limited success due to financial difficulties and political pressure.

The Solution

PES presents Plastic 2 Build (P2B), a new initiative that aims to address plastic pollution, job creation and affordable housing in one impact investment by valorizing and classifying all types of Plastic waste, a resource. It is relatively cheap, energy efficient, scalable and modular compared to other recycling projects.

Facility will manufacture high specification building materials from 100% local content, saving much needed foreign exchange, in sustainable and an environmentally friendly process with a potential to export the technology to the sub‐region.

With an initial high impact investment, we develop, a formal Ecosystem that triggers demand and supply for all types of Plastic Waste, saving municipalities millions in collection (avoid Plastic pollution), creating jobs(50% women), and wealth (household segregating at source and selling plastic waste that was previously dumped.

This waste is then consolidated and processed into building materials for the construction of affordable housing.

In January 2022, PES secured a 15-year lease of land adjacent to the Kingtom dumpsite for the manufacturing facility.

In July 2023, The Managing Director of PES visited China, utilizing funds from shareholders procured 60% of the manufacturing plant equipment for the 1st phase which arrived in late October 2023, Balance will arrive in April 2024, Commissioning in May 2024 and Operational in June 2024.

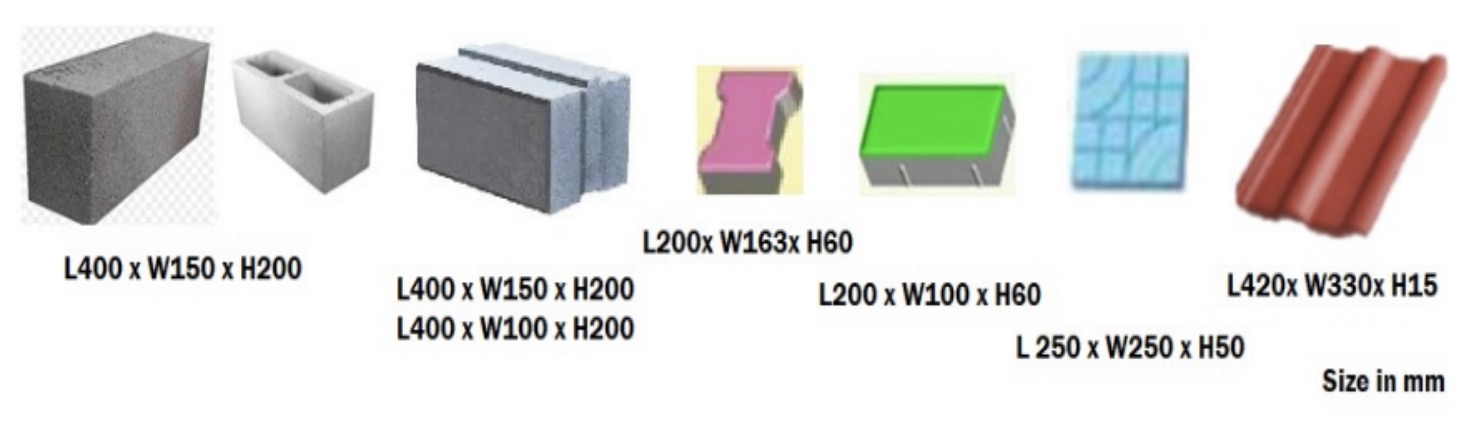

Product Range

PES split the project in 2 phases:

- Phase 1 will process 20 tons Plastic Waste/day from June 2024.

- Phase 2 an increase processing capacity to 50 tons/day in third quarter 2025, installation of a 200T/day Materials Recovery Facility (MRF) for MSW from which plastics will be extracted. These will be used to generate 1 MW/HR Electricity (Renewable Energy) for in house consumption and increase the production of blocks, pavement tiles and roof tiles.

Highlights

- Competitors are local cement block and tile manufacturers using manual labor and hydraulic machines. PES’ competitive edge

- Price (between 10%-30% cheaper).

- Strength proven to be nearly twice as strong in compression test.

- Damp prevention in buildings as it is impermeable.

- Cooler homes as roof tiles prevent sun rays penetration.

Managed by a formidable team with vast experience and network in conducting business in Sierra Leone with hands on knowledge in waste management, waste to energy and plastics recycling.

Support from both the local and central Government, the introduction of zero GST (Goods and Sales Tax), Tax holidays, Duty Free on importation of Equipment and cabinet approval of the Plastic Waste Policy in March 2023 encouraging the off take of products from recycling, PES is ahead of new players in this sector.

- Projections indicate that the business is sustainable making a decent return while achieving its social and environmental goals. It can cover its obligations and has the potential to grow as there is sufficient feedstock of plastic waste and there is a demand for affordable housing.

The impact of the Plastic 2 Build project will reach across many dimensions. Nearly 70,000 youths in Freetown are unemployed and 92.7% of people in Sierra Leone live on less than $5 a day; these people will directly benefit from creation of wealth and employment opportunities facilitated by the Plastic 2 Build project. We will provide skills training, with a special focus on women, and tricycles for our waste collectors, thus improving not only the income of people who work with us, but also their working conditions and future prospects. Affordable and resilient housing, schools, hospitals and public buildings will have a direct impact on the 60% of Freetown’s population that currently live in slums due to the lack of affordable housing. By supplying building blocks made from 100% local materials we will contribute to increasing the country’s GDP and reducing foreign exchange requirements.

Currently out of 90 tonnes of plastic waste generated in Freetown daily, 20 tonnes find their way to the legal dumpsites, Kingtom and Kissy, while 70 tonnes pollute our environment, block waterways and drains causing flooding, or are openly burnt. By diverting up to 25% of the plastic from the waste stream, we will contribute to extending lifespans of the dumpsites, unclogging drainage systems and improving air quality for everyone. Creating a market for all types of plastic waste, including the ones that cannot be recycled through conventional methods, will reduce plastic pollution and get us closer to the 40% recycling target set by the “Transform Freetown” initiative. The Plastic 2 Build project will result in savings for the local government, as less money will be required to collect plastic waste and to unclog drainage systems. Cleaner beaches will have a positive impact on the tourism industry. The most exciting part is that our solution can be adopted in other countries and benefit over 1 billion people who live in slums.